|

Jiangsu Kingshine Plastic Machine Co.,Ltd

|

| Price: | 38000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

WPC extrusion machine / PVC wall

PVC profile extrusion line consists of Conical twin-screw extruder, Vacuum forming equipment, Haul-off machine, Cutting machine, Stacker and other components, with good stability and high capacity, easy to operate, reliable. The production line can produce window or door profile, wire trunking, stair handrail and other special profiles. Our extrusion line is full automatic, energy saving and high efficiency.

Products Application

PVC profile extrusion line normally make the customerized profile for window,door frame,wire trunking, and other special profiles. The PVC profile has the performance of Non-conductive, Smooth surface, Fire resistant, Corrosion Resistance, Impact strength and so on.

Equipment list for wpc profile machine

3.1 Twin Screw Extruder SJSZ-65/132 |

3.2 Extrusion die |

3.3 Profile moulds |

3.4 Vacuum Calibrating Table |

3.5 haul-off machine |

3.6 Cutting machine |

3.7 Tilting table |

3.8 Electrical control cabinet |

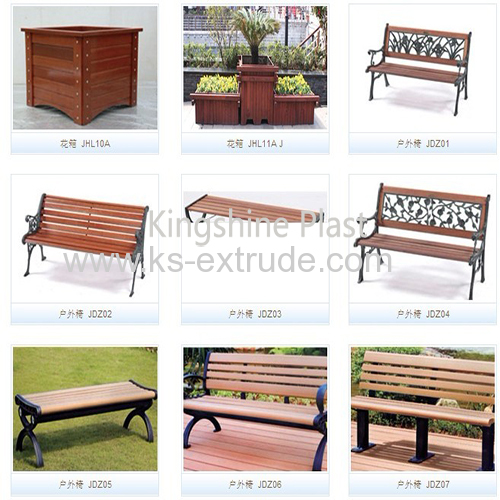

Some of our main leading products:

pvc edge banding extrusion line with three color printing machine

SPC Flooring Production Line

PVC Marble sheet Production Line

SJ-92/188 PVC WPC Door Panel Production linr of turn key project

PP,PE,PVC WPC wood plastic profile extrusion line

PVC ceiling panel, trunking profiles, door window extrusion line

pvc, wood plastic wpc production line

pvc wpc crust foam board extrusion machine line W=1220mm thickness 5-25mm CE certificated

WHY CHOOSE Kingshine?

(1) we have experiences in this field since 1980s

(2) we have our production bases in China, which shows our machine's production power

(3) we have strond technical teams and cooperate with China scientific institution to develop, improve and test our machine

(4) we have perfect service system: Our boss is devoting himself to after-sale service

We will provide the Feasibility Analysis Report for the plastic machine project.

We will provide the model design for the plastic machine plant and electric power accounting for the facilities.

We will provide the model selection and technical parameter for our plastic machine.

We will provide plastic formular according to the product requirements.

We will provide technique training for operator.

We will provide solution for the practical problem during the production.

We will install and test the plastic machineand teach customer's workers how to operate in customers' factory.

We will provide turn-key project to customers.