|

Jiangsu Kingshine Plastic Machine Co.,Ltd

|

| Price: | 130000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

High Efficient SPC PVC Floor Making Machine

Main advantage of Eans SPC vinyl flooring making machine:

1.The screw adopt the design of special mixing material function and high plasticization capacity.This guarantee the uniformity of plastic mleting,coloring and high output.

2.Clothes rack type mold die adopt double throtting design,which can make more precision of adjusting of flooring thickness.

3.The ±1℃ precision degree of temperature control can control the plasticization process,thickness and surface smooth of sheet accurately.

4.The roller position can be put by vertical or horizontal,which can give more selection basing on the different thickness of sheet

5.The screw adjusting and oil pressure press-roller double direction adjusting can control the thickness of sheet accurately.

PVC SPC flooring making machine with PLC control:

PVC SPC vinyl flooring making machine from Eans Machinery is advanced in skill and high automation.

The based material extrusion,wood grain embossing,color film,wear-resisting film.By changing lamination

paper,PVC lamination marble sheet can be made in SPC vinyl flooring making machine.

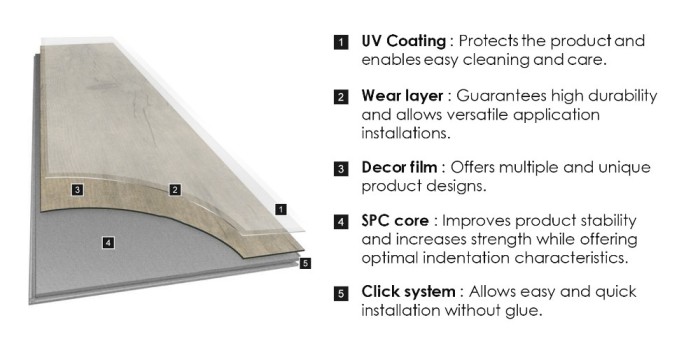

The Structure of SPC Floor

-The latest generation of PVC SJSZ-110/220 SPC/PVC Floor Making Machine.

-The capacity can reached up to 1000-1350kg per hour.

-It can produce SPC floor board, advertising board,drawer board and other products.

-Production specifications: thickness(1mm-12mm),970mm*2200mm.

-SPC/PVC sheet as flooring base board, it is online film covering and friction layer covering, after UV get a long life.

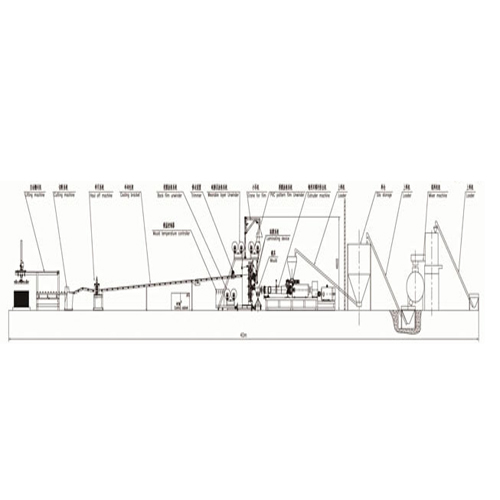

Advanced working flow

The Factory of Domestic Customer The Factory of Abroad Customer

Structure of Production Line

Equipment Details

Specifications of SPC PVC Floor Making Machine | |

Type | SJSZ110/220 |

Length of machine | 30m |

Width of machine | 2.5m |

Height of machine | 3m |

Weight of machine | 42Tons |

Width of Board | 1220mm or 970mm ,Random length |

Thickness of Board | 1-12mm |

Capacity of machine | 1000-1350kg/h |

Shipping Order

NO. | Item | Quantity |

1 | Feeder | 1 set |

2 | Conical Twin-screw Extruder | 1 set |

3 | Mould | 1 set |

4 | Calibration Table | 1 set |

5 | Haul-off | 1 set |

6 | Cutter | 1 set |

7 | Stacker | 1 set |

Service

Pre-sale service

-To provide information and market research,to provide consultation.

-To provide many kinds of conveniences and market service,etc.

-To help customers make the project planning and system requirements analysis.

-To make our products maximum to meet clients' requirements.

-To play the greatest overall economic benefits of customers' investment.

After-sale service

-To install products and test products freely for customers.

-To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

-To direct technology aspect of relevant use according to customers' requirements.

-To provide technical training for clients' employees.

-To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Technology support

-To provide installation and test for the machine.

-To provide formulas and technology of relevant products.

-To provide information of chemical material manufactories.

-To provide technical training for clients' employees.

Packaging & Delivery

Packaging Details

Standard shipping package for WPC Door Frame making machine

Port

Shanghai

Lead Time

Quantity(Sets) | 1 - 1 | >1 |

Est. Time(day) | 45 | To be negotiated |

Kingshine Plast

Kingshine Machinery is dedicated to various solutions in Plastic Machine customized to customs satisfy.