|

Jiangsu Kingshine Plastic Machine Co.,Ltd

|

| Price: | 140000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

80/156 SPC Extruder Machine Line

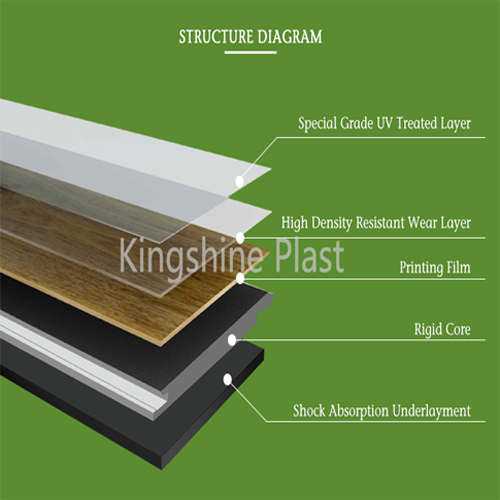

As we know, the hardwood flooring is not waterproof, so it can not used

them for bathroom. But SPC flooring is moisture resistant, also with wood

texture & stone texture, so they can use for the bathroom & kitchen.

The installation options include glue down, self-adhesive, and click. For

people who do not have the experience to install the flooring, they can choose

self-adhesive flooring & click flooring. The self-adhesive flooring also named "

peel and stick" flooring.

It makes the installation easily. Also, for some commercial places, click flooring

is designed with "Unilin" to click together. No mess, No fuss.

Application

Machinery

1.Easy to change roller.

2.Available to cover back layer.

3.High capactity.

4.High safety coefficient of producing.

5.Low cost and high profit.

NO. | ITEM | PARAMETERS |

1 | 92/188 OR 110/220 CONICAL TWIN SCREW | |

2 | WIDTH | 980MM |

3 | THICKNESS | 2-6MM |

4 | CAPACITY | 750KG/HR--1250KG/H |

Famous electrical configuration:

1. Main motor frequency controller: ABB

2. Temperature controller: Siemens PLC

3. AC controller: SIMENS

4. Thermal overload relay: SCHNEIDER

1.International famous engines, strong driving force, low power consumption,

high economic benefits .

2.Very good material for processing PVC compound and getting soomth sheet .

3.New Developed machine specially for SPC flooring , more easy to operate ,

low shrink rate and perfect surface .

4.Good material and manufactruing tecnology,specially design for SPC flooring process,economic but functional.

Work Flow

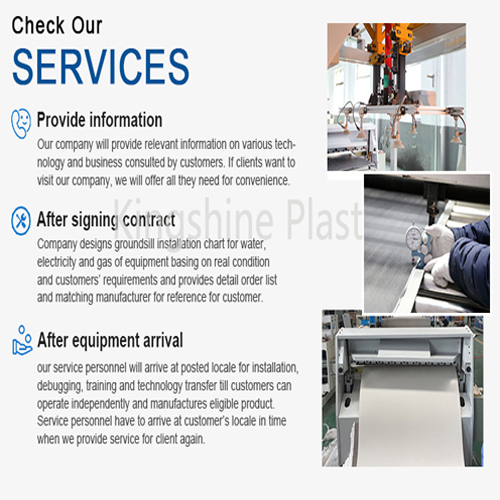

Service

Pre-sale service

-To provide information and market research.

-To provide consultation,to provide many kinds of conveniences and market service,etc.

-To help customers make the project planning and system requirements analysis.

-Take our products maximum to meet clients' requirements.

-To play the greatest overall economic benefits of customers' investment.

After-sale service

-To install products and test products freely for customers.

-To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

-To direct technology aspect of relevant use according to customers' requirements.

-To provide technical training for clients' employees.

-To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Packaging & Delivery

Packaging Details

Standard shipping package for SPC flooring making machine

Port

Shanghai

Lead Time

Quantity(Sets) | 1 - 1 | >1 |

Est. Time(day) | 45 | To be negotiated |

Technology support

-To provide installation and test for the machine.

-To provide formulas and technology of relevant products.

-To provide information of chemical material manufactories.

-To provide technical training for clients' employees.